Scientific Warehouse

About Scientific Warehouse

Warehouse of 1 lakh sq.ft. built in area with a storage capacity of 16,000 M.T. for scientific storage is available at AFTC.The main features are Water Bound Macadam flooring, Rat-trap cavity walls (Laurie-Baker technology), Glass wool insulated roof with long seamless Galvalume sheet having clip-lock system to ensure longer shelf-life for the products stored and minimise driage loss.

Because of the rat trap walls the temperature is 2 to 5 degree lesser inside the warehouse, which fetches more outturn. Conveyor Belt equipments are used for loading and unloading.

The purpose of any grain storage facility is to provide safe storage conditions for the grain in order to prevent grain loss caused by adverse weather, moisture, rodents, birds, insects and micro-organisms like fungi. In general, it is recommended that rice for food purposes be stored in Paddy form rather than milled rice as the husk provides some protection against insects and helps prevent quality deterioration.

Advantage of Our Scientific Warehouse

One incredible advantage of storing food in a warehouse is that it makes it possible for the producer of these commodities to satisfy consumers’ needs, no matter how urgent or huge the order is. This not only helps you meet the urgent demand for your goods but also ensures that your consumers’ wants are met in time, hence creating consumer loyalty.

Warehousing for food storing helps you protect your goods from elements of weather such as rain and intense heat from the sun, which can damage your goods if not addressed. If your food comes into contact with rain water, it’s only a matter of time before it all starts going bad. This is why many people prefer to store their grain harvests in warehouses.

A major challenge to food storage, especially where perishables are concerned, is keeping your food from pests and keeping it from going bad. For people that grow and harvest crops on a large scale, it may be quite a challenge to keep all this produce. This is what makes warehousing for food storing necessary.

Technologies of Our Scientific Warehouse

The ‘Rat trap bond’ is a brick masonry method of wall construction in which bricks are placed in a vertical positioninstead of a conventional horizontal position and thus creating a cavity within the wall that increases thermal efficiency, cuts down on the total volume of bricks used, and is ideal for concealing.

Advantages of Rat Trap Bond

- The cavities in the masonry act as thermal insulators. Thus, the interiors remain cooler in summer and warmer in winter.

- Rat Trap masonry uses fewer bricks and mortar reducing the cost of masonry up to 30% when compared with conventional brick masonry.

- The number of bricks used in the construction of rat trap masonry is 470, whereas, in conventional masonry, it is 550.

- Walls constructed using rat trap masonry can be used as load-bearing as well as a thick partition wall.

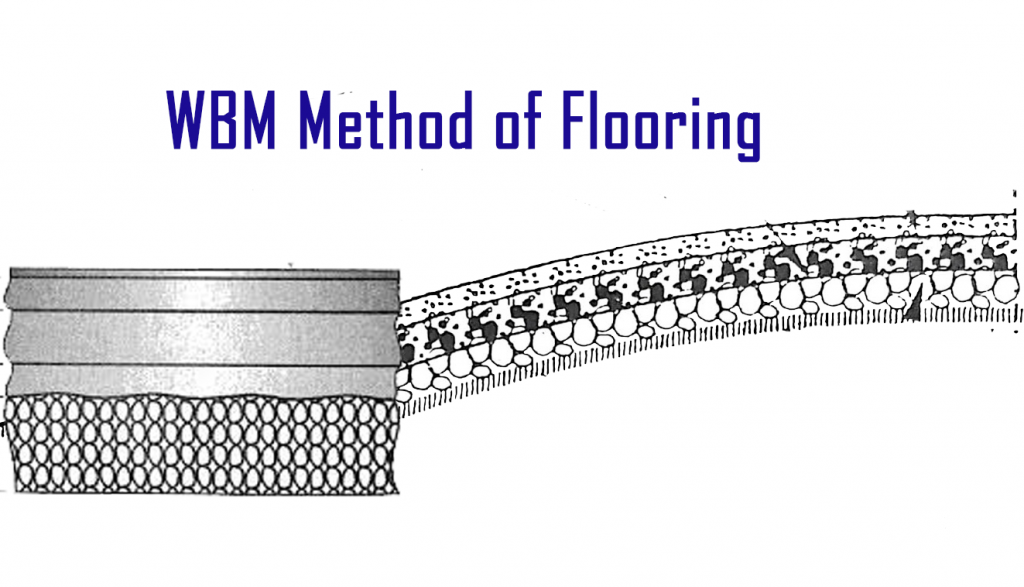

Standing for Water Bound Macadam , WBM refers to a particular type of construction where the base is built with broken stones and the top surface is bound by stone dust with the help of moisture. It is one among the methods that are most frequently utilised.

The foundation layer was constructed using rather large stones on a flat roadbed. According to Macadam, a road should always be elevated to enhance drainage in order to prevent water stagnation, which extends the life of the built-up road. Each compacted layer of Water Bound Macadam road has a thickness that varies from 10 cm to 7.5 cm and is entirely dependent on the size and gradation of the mixture utilised.

Advantages of WBM

- Given how inexpensive it is to build Water Bound Macadam, it is cost-effective.

- No specialised labour is needed to build the WBM.

- WBM are built using materials that are readily available

- If these floors are regularly maintained adequately, they should be able to withstand daily weightage of about 900 tonnes.

In pitched roofs, glass mineral wool laid at ceiling level is a common loft insulation solution. It can also be fitted between rafters when building a ‘room in the roof’, maybe as part of a loft conversion project, to provide both thermal and acoustic comfort.Glass wool Insulation is one of the most widely used forms of insulatino world-wide because of its thermal and acoustic insulation properties, light weight, hogh tensile strength and exceptional resilience.

Glass wool is the most dominant type of insulation used in applications with service temperatures between -50 oC to +250 oC.

Glass wool consist of fine, long, inorganic fibers bonded together by high temperature binder. Ther fibers (each of approx. 6 – 7 microns diameter) are distributed in such a way as to trap millions of tiny pockets of air in the product, thereby creating its excellent thermal and acoustic insulation properties. the product is light gold in colour and its superior tensile strength and resilience makes the product ideal for applications in which there will be vibration, jolting or high compression. The light weight and handleability of Glass wool also offers significant advantages during transport and installation. In addition, Glass wool is chemically inert and has no impurities such as iron shots, sulphur and chloride. The product is non corrosive to metal and does not support mold grow.

Advantages of Glass Wool Insulated Roofs

- Glass wool insulatorsare certified as soluble, which makes them safe.

- Flexible and damage resistance

- Noncombustible and heatproof.

A stacker is a large machine used in bulk material handling.Its function is to pile bulk material such as limestone, ores, coal and cereals on to a stockpile. A reclaimer can be used to recover the material

Stacker cranes are commonly used in warehouses and other storage facilities to move goods, materials, and equipment within and between locations. Compared to forklifts and conveyor systems, they are much more versatile since they are less limited by aisle size.eightage of about 900 tonnes.